Water is the most essential ingredient in beer, and arguably the most underappreciated. It accounts for over 90% of the final product and is used in a variety of ways in brewery operations, from cleaning tanks to steam generation and wort cooling. But, as the brewing industry faces growing pressures from water scarcity, climate variability, and tighter regulations, managing water use efficiently and treating effluent responsibly are no longer just best practices; they are business requirements.

Conservation was once seen as a cost; it is now recognized as an opportunity for operational excellence, regulatory compliance, and brand leadership. This article draws on experience and insights to explore how breweries can do more with less and lead the charge toward sustainable water stewardship.

The Brewing Industry’s Water Footprint

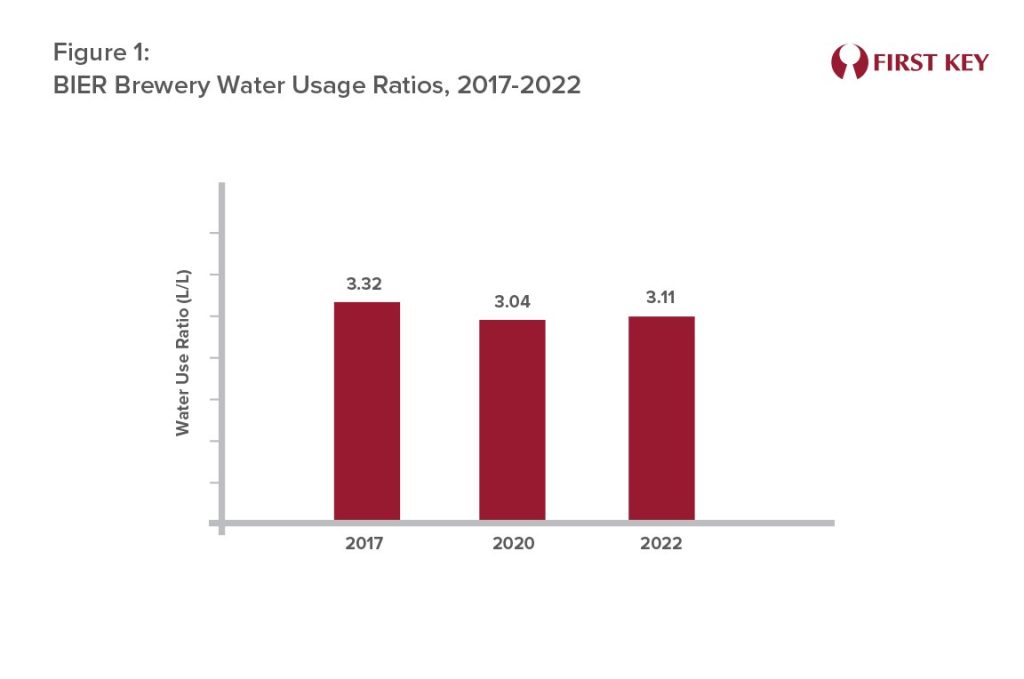

Historically, breweries have used between 3 to 6 hectoliters of water for every hectoliter of beer produced. Since 2017 that ratio has been getting closer to an average usage of approximately 3 hL of water/hL of beer as shown in Figure 1 below [1]. The ratio has improved over time, thanks to better process controls and investments in efficient technologies, and some breweries have achieved ratios well below 3 hL/hL. Still, the opportunity for improvement exists for most breweries, as even at the lower end of that range, significant volumes of water are consumed, and just as much is discharged as wastewater. For breweries seeking to reduce their environmental impact, understanding how water is used across the operation is critical.

Conducting a brewery-wide water balance helps uncover inefficiencies, identify leaks, and benchmark performance. It also establishes a baseline for setting meaningful reduction targets. Mapping where water enters, where it’s used, and how it exits as effluent allows breweries to make smarter, data-driven decisions about where to invest in improvements.

Why Water and Effluent Management Matter

Water is no longer the cheap, abundant utility it once was. Globally, water scarcity affects more than half the population for at least part of the year, and climate change is only intensifying those risks [2]. For brewers, the consequences of water-related disruptions are not hypothetical; they are operational and financial realities. Supply chain disruptions, community conflict, and permit delays can all stem from poor water practices.

Effluent management adds another layer of complexity. Brewery wastewater is nutrient-rich and loaded with organic material. If not treated properly, it can degrade local water bodies and violate environmental regulations. Beyond compliance, there’s a broader expectation now: consumers want brands to act responsibly, and retailers and investors are starting to demand it.

Strategies for Reducing Water Consumption

Reducing water use in breweries should start with data-driven process optimization. Even modest changes, like installing flow meters for real-time monitoring, fixing leaks, or improving rinse cycles, can yield immediate benefits. For new or expanding facilities, embedding efficiency into the design from the outset pays dividends. Centralized CIP systems, for example, allow cleaning solutions to be reused multiple times, reducing both water and chemical use.

Advanced technologies like high-efficiency spray nozzles or gamma jets, and decanters can minimize extract loss and improve cleaning effectiveness without increasing water consumption. High-gravity brewing, which produces concentrated wort that’s diluted later in the process, also offers significant savings by reducing the amount of water used during mashing and boiling, and in the water used for cleaning the tanks that handle the high-gravity beer.

Water reuse is also gaining traction in breweries of all sizes [3]. Reclaiming and treating process water for use in non-potable applications such as irrigation, cooling towers, pump seal water, or initial rinses is increasingly seen as both feasible and responsible. While regulatory constraints still limit reuse in some regions, innovations in treatment technology are making these solutions more accessible.

Understanding Brewery Wastewater and Effluent

Brewery wastewater is characterized by high biochemical oxygen demand (BOD), total suspended solids (TSS), nutrients like nitrogen and phosphorus, and residual cleaning agents. These pollutants require thoughtful management before discharge [4]. Understanding the characteristics of each process stream, e.g., brewhouse, fermentation, filtration, packaging, and cleaning, is essential to designing an effective treatment strategy.

Most breweries use a combination of primary and secondary treatment. Screening and clarification help remove solids and reduce organic load before the water enters biological treatment stages. Aerobic and anaerobic digesters break down organics. In the case of anaerobic digestors, these produce biogas, which can offset energy use. Membrane bioreactors (MBRs) and moving bed biofilm reactors (MBBRs) are compact, high-performance technologies that are particularly well suited for space-constrained sites.

The regulatory landscape is increasingly strict, with U.S Clean Water Act compliance and National Pollutant Discharge Elimination System (NPDES) permitting now requiring more detailed effluent monitoring and reporting [5]. But, beyond the mandate lies an opportunity; breweries that get ahead of these requirements are often rewarded with greater operational stability and community goodwill.

Best Practices in Wastewater and Effluent Management

The BIER Water Circularity Playbook offers a practical framework for breweries ready to elevate their water stewardship. It advocates for a holistic, lifecycle approach to water, one that integrates circularity principles, stakeholder engagement, and continuous improvement [2].

- Source Reduction and Segregation – Isolate high-strength streams, such as fermentation blowoff or CIP discharge, for targeted treatment. This reduces the burden on downstream systems and enables resource recovery (e.g., energy and nutrients).

- Primary and Secondary Treatment Technologies – Use layered systems, physical separation, biological digestion (aerobic and anaerobic to break down organics), and, where needed, advanced filtration. Each stage improves water quality and enhances efficiency.

- Collaboration and Partnerships – Breweries can work with municipalities or neighboring industries to reuse treated effluent for firefighting, irrigation, or street cleaning. These partnerships extend the lifecycle of water and build strong community ties.

Real World Examples and Innovations

At The Alchemist Brewery in Vermont, side-streaming and anaerobic digestion are used to treat concentrated effluent streams, turning waste into energy. The brewery also employs centrifugal separators and closed-loop systems to reduce solids and enable reuse [6]. In Latin America, breweries have formed off-site partnerships that repurpose treated effluent to irrigate parks and support agricultural activities. These initiatives help reduce freshwater withdrawals while contributing to the health of surrounding ecosystems [7].

An example of water-saving innovation in packaging comes from Stoneface Brewing Co. in Newington, New Hampshire. The brewery replaced traditional water rinsers on its canning line with an ionized air rinsing system, a technology that uses ion-charged compressed air to clean cans without introducing moisture. The switch, implemented in collaboration with the New Hampshire Department of Environmental Services’ Pollution Prevention Program, allowed Stoneface to save approximately 36,000 gallons of water per year, eliminating the need for residual water removal before filling, and improving overall packaging efficiency. Beyond the measurable conservation benefits, the brewery also reported reduced maintenance downtime and extended equipment life by minimizing moisture exposure on the line. The initiative illustrates how relatively small process modifications, like transitioning from water-based to dry-cleaning technologies, can yield outsized sustainability gains while maintaining product quality and line hygiene standards.

Stone Brewing has explored greywater reuse and invested heavily in efficient CIP systems [9]. Across the board, these breweries have shown that environmental stewardship and cost efficiency are not at odds; they are deeply intertwined. At Denmark’s Fredericia Brewery, 90% of all process water used in beer production is recycled. This achievement has reduced the brewery’s water usage to just 1.4 liters per liter of beer produced, setting a new benchmark for sustainable brewing practices [10].

Overcoming Challenges

Despite the benefits, implementing water and effluent improvements can be daunting, especially for legacy facilities. Upgrading infrastructure often requires significant capital investment, and retrofitting modern systems into existing plants adds operational complexity. Even when the technology is available, aligning internal stakeholders around long-term sustainability goals can be as difficult as the technical work itself. In many breweries, the perception persists that water is inexpensive and plentiful, making it harder to justify investments that deliver savings in efficiency and compliance rather than immediate increases in production.

The breweries that succeed in overcoming these barriers tend to focus as much on people as on equipment. Training operators, brewers, maintenance crews, and support staff helps ensure that everyone understands their role in using water wisely and spotting inefficiencies. Building a culture of water stewardship, where water management is treated as a shared responsibility, creates momentum that reinforces investment in infrastructure. Digital dashboards that are integrated into the brewery’s KPIs, as well as real-time monitoring tools, can support this cultural shift by making water use visible and actionable, helping teams identify issues early and celebrate improvements when targets are met.

The Path Forward: Continuous Improvement and Innovation

The most forward-looking breweries understand that water stewardship is not a one-off initiative but a continuous journey. They are investing in smarter tools such as automated controls, digital dashboards, and advanced treatment systems, not just to meet today’s regulatory requirements but to anticipate tomorrow’s challenges. By embracing digitalization, breweries are now able to monitor water use in real time, detect leaks, and predict inefficiencies before they escalate into costly problems. This shift toward proactive management ensures not only compliance but also greater operational resilience in the face of changing environmental and regulatory pressures.

Equally important is the adoption of context-based and science-driven strategies that align brewery goals with local watershed conditions. The True Cost of Water Toolkit, for example, helps quantify hidden costs such as energy, treatment, and opportunity loss, strengthening the business case for smarter water use [2]. As breweries set more ambitious targets for water reduction and effluent quality, collaboration across the industry becomes critical. Sharing best practices and engaging with technology providers, peers, and local communities accelerates progress, ensuring that sustainability extends beyond individual facilities and into the broader ecosystem.

Two decades ago, water was an operational line item. Today, it is a strategic resource and a shared responsibility. The breweries that recognize this shift and act accordingly will not only secure their license to operate but will also lead the industry into a more sustainable future. Producing more beer with less water and cleaner effluent isn’t just possible, it’s already happening. The tools, technologies, and frameworks are in place. Now it’s up to each brewery to take the next step.