A Technical Overview of Cannabis Beverage Production

Cannabis and hops have long been considered “cousins” by brewers and cannabis aficionados. Indeed, both species belong to the same family of plants, Cannabaciae, and both produce many of the same terpenoid compounds. Because of this, many brewers have wondered if a typical hop bill can be augmented or replaced with cannabis. This article provides some quality context in this regard and serves to help a brewer to optimize the use of cannabis in the process.

First, it should be stated that currently, cannabis is classified as “marijuana” a Schedule 1 drug by the Drug Enforcement Administration (DEA) when it contains more than 0.3% dry weight THC. Marijuana is federally illegal in the United States. Cannabis containing less than 0.3% dry weight THC is classified as “hemp” and is federally legal per the 2018 Farm Bill, but still not allowed by the TTB to be used in any alcoholic beverages per their 2019 circular. Several states, such as Colorado and California, have legalized the use of marijuana and hemp in non-alcoholic beverages and food products. Given this, the following text will assume that any work with cannabis is carried out in those regions of the U.S. and where it is legally permissible.

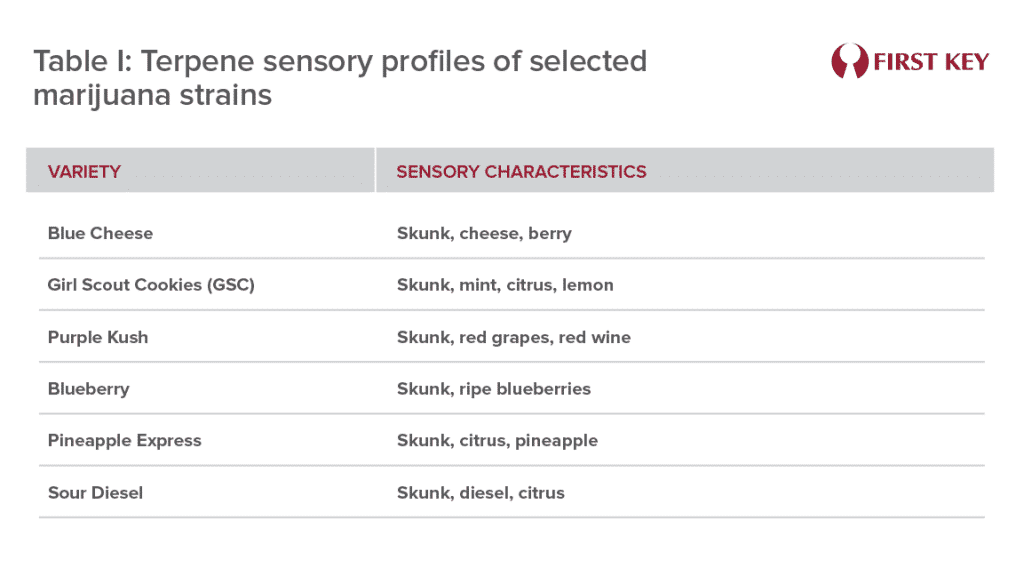

When comparing hop products to cannabis products, aside from the visual differences, a brewer will notice obvious aromatic differences. Cannabis has an overwhelming, dank smell that is very similar to the light-struck aroma of beer. Indeed, this telltale aroma has been identified as 2,3-MBT.[i] Beyond this typical brewer’s off-note, cannabis varieties have terpene sensory profiles that resemble those of hop varieties (Table I). A question arises then that if a brewer can cancel out or mask the light-struck aroma, can cannabis varieties be used like hop varieties to obtain unique flavor profiles in beer? The answer is, possibly. A poster published in 2020 showed that the sensory aspects of MBT in beer can be minimized by the addition of a very small amount of copper ions.[ii] Additionally, it was shown that copper addition can prevent and reverse the aroma of MBT. In this regard, it is theoretically possible to expose cannabis material to copper in order to “clean up” the light-struck aroma and allow the varietal terpenes to be showcased in a similar manner to the way hop varieties are showcased in many hop-forward beer styles, such as IPA. In other words, cannabis varieties such as GSC could be used to highlight aromas of mint and citrus, while Pineapple Express could highlight tropical aromas of pineapple and citrus.

An unmentioned aspect of cannabis is that isolated cannabinoids, such as CBD and THC do not have an aroma component but do have a bitter flavor component which is complimentary to naturally occurring bitterness in beverages such as beer. Depending on the base liquid makeup, 10 mg of cannabinoids will add a perceived bitterness equivalent to about 2 – 4 IBU. However, cannabinoid bitterness is not measurable with current hop IBU measurement methods, and so newer methods will have to be developed to quantify the bitterness contributed by this novel ingredient. Until such methods are developed, units such as Perceived Cannabinoid Bitterness Units can be considered. Brewing recipes will need to compensate for cannabinoid bitterness by decreasing the bitterness contribution from hops to create desired taste profiles.

If the bitterness of cannabinoids is not wanted in a particular beverage, such as hard seltzer, then the brewer will need to find an appropriate masking or blocking solution. Fortunately, several strategies have been identified, including the use of table sugar, sodium chloride or mycelial preparations from mushrooms.[iii]

Another important choice to make when adding cannabis to a brew is the addition point – hot side or cold side. From a financial perspective, hot side addition could be very costly. Losses of cannabis components on the hot side have not been measured but could be similar to those of hops which are in the order of 60 to 70%. Cannabis buds are significantly more expensive than hop cones and so cold side addition, with reduced losses, is a better alternative. However, similar to hops, cannabis components are not very soluble in water-based solutions. Luckily, newer technologies have emerged which allow these components to be converted into water-compatible ingredients. In essence, hydrophobic compounds such as terpenes and cannabinoids can be processed in a few steps to make them useful as cold-side additives, as described in the following sentences. First, these components are extracted using CO2, or other methods similar to those used for hop extraction. Second, the extracts are heated to decarboxylate cannabinoids into pharmacologically active components. Typically, this step is carried out at about 110 degrees C for 30 minutes, which is similar to the “activation” or isomerization of alpha-acids in the brewing process. Then, they are mixed with a carrier oil, which can be almost any plant-based oil, taking care to identify any potential allergens, such as peanuts. This carrier oil encapsulates the hydrophobic material and allows for a more homogenous dispersal. Then the encapsulated material is emulsified with an agent such as Tween 80 or lecithin, and ultrasonicated to create ultra-small particles in the desirable size range of less than 1000 nm. These nanoparticles can then be added to water-based solutions, such as beer. Although these general steps in achieving water compatibility can serve as a starting point, a brewer will need to ensure that the quality aspects of finished beer are not affected negatively, such as foam stability, clarity, and taste/aroma.

After getting cannabinoids into beer, another quality aspect to track is cannabinoid potency. A decrease in potency can usually be traced to either high oxygen levels or adherence to can liner material. Regarding oxygen levels, a brewer is well served if dissolved oxygen (DO) levels in packaged beer are kept as low as possible for both beer quality and cannabinoid stability. More research is required in this area, but at the present time DO levels below 200 ppb in the package are generally adequate to avoid oxidation of cannabinoids. DO levels above 400 should be addressed and minimized to avoid oxidation of cannabinoids and beer. DO levels above 1000 ppb should be avoided.

Adhesion of cannabinoids to can liners is an issue that also should be investigated if potency decreases over time. In this regard, changing carrier oil and/or emulsifying agent should be investigated. Alternatively, purchasing a pre-made emulsion that is formulated to avoid adhesion should be looked into as several companies exist who specialize in emulsion technology. Finally, the can supplier should also be consulted to see if they produce can liners that minimize cannabinoid adhesion.

If pasteurization is required, cannabinoids and terpenes should be able to withstand standard beer pasteurization temperatures. THC has been studied during processing and found to be relatively stable up to 200 degrees C.[iv] Typical pasteurization regimes for beer are generally safe for cannabis-derived additives.

In summary, the addition of cannabis to beer and beverages can be carried out. However, proper planning with respect to potential quality issues will help ensure a successful outcome.

By Dr. Keith Villa

[i] Identification of a New Family of Prenylated Volatile Sulfur Compounds in Cannabis Revealed by Comprehensive Two-Dimensional Gas Chromatography. Iain W. H. Oswald, Marcos A. Ojeda, Ryan J. Pobanz, Kevin A. Koby, Anthony J. Buchanan, Josh Del Rosso, Mario A. Guzman, and Thomas J. Martin. ACS Omega 2021 6 (47), 31667-31676. DOI: 10.1021/acsomega.1c04196

[ii] Villa, Keith, and Catherine Villa. 2020. “Prevention and reversal of the formation of light-struck (3-Methyl-2-butene-1-thiol) aroma in beer.” e-Poster presented at the World Brewing Congress WBC Connect 2020 [online meeting], September 19, 2020. https://brewing.confex.com/brewing/2020/meetingapp.cgi/Paper/1466

[iii] Purdy, Chase. July 16, 2016. Researchers have finally discovered the key to naturally stripping sugar from all our foods. Quartz. Updated January 4, 2022. https://qz.com/732128/researchers-have-finally-discovered-the-key-to-naturally-stripping-sugar-from-all-of-our-foods/.

[iv] Repka MA, ElSohly MA, Munjal M, Ross SA. Temperature stability and bioadhesive properties of delta9-tetrahydrocannabinol incorporated hydroxypropylcellulose polymer matrix systems. Drug Dev Ind Pharm. 2006;32(1):21-32. doi:10.1080/03639040500387914