Why are craft brewers and distillers willing to pay two, three or four times as much per pound for malted grains from small, independent craft malthouses than from the multi-national malthouses?

Among the nearly 8,000 craft brewers and 2,000 craft distillers in North America today, most are striving to separate themselves from all the rest through quality, brand differentiation and “terroir”, a French word meaning “sense of place”. Wine, cheese and chocolate makers have depended on and marketed terroir for many years. Customers have shown their willingness to pay several times the standard price for the story and unique flavors associated with terroir.

In the 18th and 19th centuries, malt was typically made adjacent to and as part of the individual brewery or distillery. During the 20th century, third party commercial sales malthouses began building bigger and more automated malthouses in order to reduce costs through economies of scale. These large commercial malthouses replaced virtually all of the distillery and brewery-owned malthouses (with the notable exception of Coors in Golden who has retained their 100% malting capability for 75 years). The top 20 malting companies worldwide produce nearly 24,000 tons of finished malt in twelve hours, while all North American craft malthouses that are in operation today will take a full year to produce an equivalent amount of malt! Most, if not all, of these large commercial maltsters have amped up marketing aimed at craft breweries in order to capture some of this rapidly growing business. Recently, mid-scale malthouses (10,000 to 50,000 ton annual capacity) are being built in Colorado, Delaware, New York, Ohio and Canada attempting to capture some of the lucrative craft beer and spirits market.

The craft brewer of today is in the middle of a minor revolution in choosing and promoting new hop varieties that give them unique flavors, terroir, brand identity and a story to pass on to their customers. They are now, collectively, turning their attention in the US to the largest single dry ingredient used in brewing, namely malt. When asked, many of them bemoan the fact that malt has become a commodity, with flavors, malting characteristics and processes dictated by the big, multinational breweries and they are impatient to see a revolution in malt akin to the craft hops success story they made happen and are willing to pay dearly for.

Unique malt and beer flavors that have been reported by craft brewers from craft malt made for them include “…bready, malty, milk chocolate, dark chocolate, fruit cake, pound cake, roasted, toasted, biscuity, caramel, coffee, toffee, cacao, smoky, kola, almond, hazelnut, raisins, prunes, figs, vanilla, clove, honey, marmalade, peanut butter, cinnamon, sour, sweet, bitter, sharp, creamy, grassy, earthy, mesquite, candy, bran flakes, sourdough, graham crackers, Grape Nuts, toasted marshmallow and woody…”

In 2003, Michael Lewis, Professor Emeritus of Brewing Science at University of California—Davis, suggested that US malt was made almost entirely for big brewery lager and light beer mashes diluted with up to 40% non-malted adjuncts, prinicipally corn and rice. Lewis postulated that brewing all-malt craft beers with this malt might be “…too much of a good thing for craft brewers and, hence, unsuitable.” Professor Lewis went on to say that standard lager malts have too much diastatic power, alpha-amylase activity, free amino nitrogen, lipids, polyphenols, and extraneous enzymes like lipoxygenases as well as being too variable within and among malted barley kernels because of huge malt batch sizes. (Malt, the Beauty and the Beast- An Appraisal for Craft Brewers, MBAA TQ, 40, 3, 2003 pp. 186-188).

Professor Lewis estimated that malts made for adjunct brews would contribute twice the enzymatic activity necessary for normal starch conversion in an all-malt craft brew. These malts also would yield higher amino acids, peptides and proteins that are known to affect yeast growth, beer foam and mouthfeel of finished beer. High residual levels of these nitrogen-compounds may also contribute to higher beer pH and haze and increased potential for the growth of microbial beer-spoilage organisms in all-malt craft beers. Professor Lewis suggested that malts for all-malt craft beer should be produced differently than those made for adjunct brews in order to accentuate the positive (Beauty) and minimize the negative (Beast) aspects of malt in beer.

The Brewers Association (Boulder, Colorado) published a white paper entitled “Malting Barley Characteristics for Craft Brewers” in April, 2014. After a 36-month BA member survey, it was revealed that to produce all-malt beer brands, craft brewers seek barley malts with:

> distinctive flavors and aromas

> lower free amino nitrogen (FAN)

> lower total protein

> lower diastatic power

> lower Kohlback index (soluble/total protein ratio)

In March, 2018 Joseph Hertrich, retired director of malting for Anheuser-Busch Brewery, discussed “Challenges of All Malt Brewing with North American Two-Row Malting Barley” at the MBAA Eastern Technical Conference. Hertrich explained how key malt modification parameters have changed over time and can be detrimental in brewing all-malt craft beer today. According to Hertrich, the last few decades of breeding, malting and brewing process changes have increased agronomic yield, shortened steeping and germination times, reduced seed dormancy, increased malt modification profiles and pre-harvest sprouting tendencies, lowered malt and beer color and raised brewhouse yields, enzymatic activity and protein modification levels which has resulted in thinner (more highly attenuated), lighter beers with lower foam quality and poor flavor stability.

In addition, 6-row malting barley variety acreage has shrunk to less than 10% of the total US barley crop due to disease and displacement by GMO-corn and soybean farming in the midwest. It has been predicted that 6-row barley will dissappear entirely from US production in just a few years. Most brewers worldwide agree that 2-row barley is superior to 6-row barley for malting and brewing, while 6-row is mainly used for distilling and animal feed.

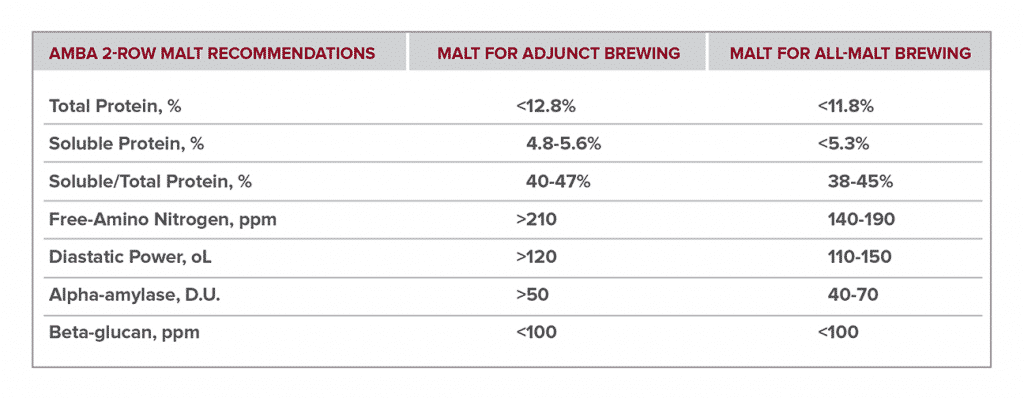

During this same time period, AMBA (the American Malting Barley Association) recognized the same trends in malt produced mainly for adjunct brews and in March, 2018 published separate guidelines for 2-row barley malts to be used in adjunct brewing and all-malt craft brewing, shown here:

Since most commercial malthouses and brewers with their own malthouses in the US today still produce malts mainly for adjunct lager beers, representing more than 85% of US beer production, a supply shortfall in production of malt for the growing all-malt craft beer market has been created, leading to today’s burgeoning craft malting movement. The Craft Maltsters Guild (Hadley, Massachusetts) estimates that nearly 100 new craft malthouses are in operation, with a similar number in planning or construction.

Most of the operating craft malthouses in America today are at the limits of their production capacity and are planning ways to expand their production. Since they are all in their first few years of craft malting, they are willing and routinely share information and best malting practices with each other through networks like the Craft Maltsters Guild, the Brewers Association, the Master Brewers Association of the Americas and the American Malting Barley Association.

Brewers and distillers use 87% of all non-feed barley production in the US. In 2017, while overall US beer sales was down 1% year-over-year from 2016, craft beer sales increased by 5%. “Mega-breweries” beer production and sales are dominated by light beer brands that call for 30-50% non-malted adjuncts in their brewing recipes while craft breweries brew nearly all of 100% malt (no adjunct) beer. This fact, coupled with the higher attenuation (fermentation rate) and increased dilution rate of packaged light beers, means that all-malt craft beers require up to four times as much malt per packaged barrel of beer. Currently, nearly 50% of the malt made from malting barley is finding its way into craft beers. It is projected that the balance will keep increasing toward craft beer usage and, very soon, a larger portion of the US malt production will be used in all-malt craft beer production rather than large brewery light adjunct-containing lagers.

Brewer-maltster-farmer partnerships are being created every day that combine grain terroir with the personalities that grow and malt the grain. To brewers and distillers, the additional cost of brewing materials (which is a fraction of packaging material costs for those breweries that can or bottle their beers) is well worth the “branding” that can brag about barley from unique soil conditions or barley varieties or stories about local maltster families and bespoke malting processes that can only be found in their beer.

Questions to answer in your business plan prior to plunging into craft malting:

1. How much of your malt product will find its way into your own beer, spirits or foodstuffs?

2. Will your malthouse have an anchor at the front end i.e. self-production of grains for malting, or the back end i.e. use in your brewery or distillery?

3. What % of self-made vs. commercially purchased malts is in your business plan? How will you handle future expansion of your beer, whiskey, etc.?

4. How much labor vs. upfront capital equipment costs are you willing to invest? i.e. floor malting requires manual shoveling every 8-12 hours during germination while pneumatic and drum maltings can be turned via machines, often automatically.

5. How important is the story of local grains, locally malted and sustainability to your business plan?

The same local, terroir and sustainability factors that compel more and more people to walk into their local pub breweries for a craft beer, rather than buying beer from multi-national corporations, is alive and well in the entire brewing supply chain, urging craft beer and spirits drinkers to ask “Where does your malt come from?”

All of this adds up to the perfect time today for those who have the desire and patience to turn hard, insoluble grains of barley, wheat, rye, oats, triticale, spelt, quinoa, millet, milo, buckwheat, rice, teff, sorghum, amaranth, corn and even sunflower seeds into sweet, colorful, enzyme-packed bundles of malt sugars, colors and flavors. Indeed… if you build it… they will come!

Dave Thomas has been a maltster and brewer for 43 years, is the author of The Craft Maltsters Handbook (White Mule Press, 2014), a member of the board of the Craft Maltsters Guild and Senior Craft Malting Adviser for First Key Consulting.