Over the past two years there has been a significant increase in activity in the brewing supply chain to formalise action on greenhouse gas (GHG) reduction. Businesses and private citizens must collectively ensure that they align with an emissions reduction pathway that will deliver the maximum 1.5°C global average warming that is critical for continuing life as we know it. After the 26th UN Climate Change Conference of the Parties (COP 26) in Glasgow, Scotland, there is talk of greater requirement to publicly report GHG reduction plans and incorporate them into a series of time-stamped milestones that will be realised by the pivotal date of 2050 at the latest.

Although many commentators tell us we are 20 years too late starting, there is real urgency and focus now to try to recover. It is easy to become disheartened by those who describe insurmountable obstacles that could lead to missing the target. On the contrary there is much to celebrate in terms of those who can see the transformation possible right now with existing technologies. There is still an urgent need for development of new carbon efficient technologies and cross-sector action, but what we can achieve now will set us on a course that has a greater chance of success than business as usual.

There can appear to be a significant financial barrier to reach net zero. Estimates range up to 60% increased spending, but many companies and countries recognise that it should be possible to reach net zero carbon with net zero cost to business operations. That equation is a balance of reduced operational cost through efficiency and new technology and the avoidance of the penalties, legislative or otherwise, that come from inaction. The global challenge here is to accelerate the spending up to 2050 some 6 times greater than in the period in which the problems have been created. Abatement costs can be substantial, payback will be longer, but the challenge, whilst difficult, is possible.

The transition calls for collective and global action and will only succeed through collaboration across sectors and geographies. However, the impetus to make such changes can be heavily influenced by inspirational case studies such as within the malting and brewing world that show the art of the possible in achieving GHG reduction. Major brewers such as ABInbev at Magor, UK are installing hydrogen generation and self-generating energy for use on site[1]; Heineken are one of the brewers promoting hydrogen in their transportation network[2]. Others promote genuinely new green electricity generation from external suppliers by linking to new wind farms or other sustainable sources; targeting specific factories to become net zero within 5 years; creating carbon negative raw materials that can generate high quality insets to balance carbon budgets and many more. Some commentators estimate that with technology available right now we could achieve 85-90% GHG reduction. The key is to identify a suite of options for carbon reduction and not expect one solution to provide a silver bullet.

A roadmap should not just be about GHG reduction it must include targets for food waste, packaging, biodiversity, and water conservation. As such it becomes a sustainability roadmap focussed on carbon reduction where possible but including other areas which indirectly have a beneficial impact on carbon reduction. It is important to establish if the roadmap will really deliver on the plan to become net zero. The term is widely interpreted and often misused. For example, there is no such thing as a zero-emission process. Everything emits GHG relevant emissions at some point in its manufacture, use or disposal. The term net zero reflects that and requires a removal of carbon from the atmosphere at least equivalent to the generated emissions. Technologies that enable a process or business to get to net zero are said to neutralise the residual impact, hence carbon neutral.

One of the foremost benchmarks for defining progress that deliver global impact is the science-based target initiative[3]. It established goals for carbon reduction by industry sector and prioritises internal action over reliance on buying carbon credits. Offsetting should never be the first choice and businesses must look for internal carbon savings opportunities in the near term as clearly identified by the Oxford Principles[4]. Where necessary, credits can be purchased as offsets, carbon credits from projects that are outside the immediate supply chain, or insets, those generated within the supply chain. Examples of offsets could be tree planting, bioenergy with carbon capture and storage or direct air capture. There are the avoiding actions too such as preventing deforestation, generating renewable energy. An inset could be credits delivered by programmes to provide carbon negative malting barley i.e., that which is grown using regenerative agriculture and cover cropping which removes more carbon than is generated in growing the barley.

Setting the boundary for measuring carbon impact is important. Much is made of lifecycle analysis, but this can be extremely onerous to undertake. Such analysis may not deliver specific actions that are within the grasp of a given business. Hence it is more advantageous to define a linear boundary such as farm to brewery. It is always possible to start with a narrower scope and collect robust data whilst being aware of the carbon shadow and the impact of the operations beyond the boundary that has been defined. Such an approach is referred to as an expansive boundary by the science-based targets programme. An ever-widening scope is effective by starting small and working on big win areas first, then expanding the data gathering more widely along the supply chain to reach as near to full coverage as is possible by the target date. It is also common now for external platforms such as BCorps, the Suppliers Ethical Data Exchange (SEDEX) or EcoVadis to include labour and human rights, business ethics and health and safety in a sustainability programme. This reflects the ten principles of the United Nations Global Compact[5].

A carbon footprint has three scopes and has an impact upstream (things coming into the manufacturing operations) and downstream (the impact of goods dispatched from the factory forward into retail). Emissions are also described as being direct (emissions the factory directly controls) or indirect (emissions generated outside direct operations).

Scope 1 – Direct emissions generated from use of fuels, e.g. natural gas and fuel oil and on-site generation of electricity, heat, or steam. Directly owned and operated transportation fleet emissions also form part of this impact.

Scope 2 – Indirect emissions associated with consumption of purchased electricity, heat, steam and cooling, but generated at sources controlled by others.

Scope 3 – Indirect emissions that are not captured in scope 2. They can occur upstream or downstream. Examples of scope 3 emissions are business travel by means not owned or controlled by the organisation, waste disposal which is not owned or controlled, or purchased materials or fuels. Scope 3 forms the greatest proportion of the carbon footprint of most companies (likely in excess of 60%) and can be the most difficult to calculate. For scope 1 and 2 generally there is an invoice with consumption data which is easy to convert to a carbon emission value.

- Upstream: includes growing of malting barley, transportation into the brewery; business travel in transportation that you do not own directly; employee commuting; transportation and distribution losses for the electricity one purchases externally (remember the invoiced usage is already in scope 2).

- Downstream: includes transportation to the customer; leased assets; impact of financial and other services.

Scope 3 downstream emissions are the most difficult to calculate, hence it is pragmatic to use a model developed to estimate carbon emissions relative to financial spend in those areas.

What areas of the supply chain should be included in a carbon roadmap?

Strategy:

- Develop a carbon roadmap which is aligned with a 1.5°C future climate rise model

Data:

- Determine scope 1 and 2 emissions profile

- Estimate external scope 3 emissions using financial prediction tools.

- Require suppliers to engage in sustainability certification and provide carbon data

Reporting:

- Publish an annual sustainability report

- Set realistic targets and report progress for energy, water, regenerative agriculture, social compliance

- Introduce internal carbon price to drive investments

Certification:

- Introduce external certification such as ISO14001,

- BCorp, Suppliers Ethical Data Exchange (SEDEX)

- Match the UN Global Compact principles and include Environment; Labour and Human Rights; Health and Safety; Business Ethics

Supply Chain:

- Introduce a code of conduct that requires alignment with Science Based Targets and incorporates the UN Global Compact principles

Buildings:

- Ensure insulation is the best available and all utilities on site are the most efficient available

Operations:

- Energy and water management and targeting plan in place.

- Continuous review of efficiency in place.

- Do not wait for new technology. Make the most of what is available now

Organizational Structure:

- Never make sustainability a separate activity in the company it is multifaceted and needs all functions involved: HR for the social and ethical side; production for efficiency; technical for certification; marketing for sharing best practice; finance for assessing the impact on profit and consequence of taxation or offsetting costs; sales to use your progress to retain existing clients and gain new business based on a strong and openly disclosed sustainability performance

What progress have brewers already made and what technologies are being employed?

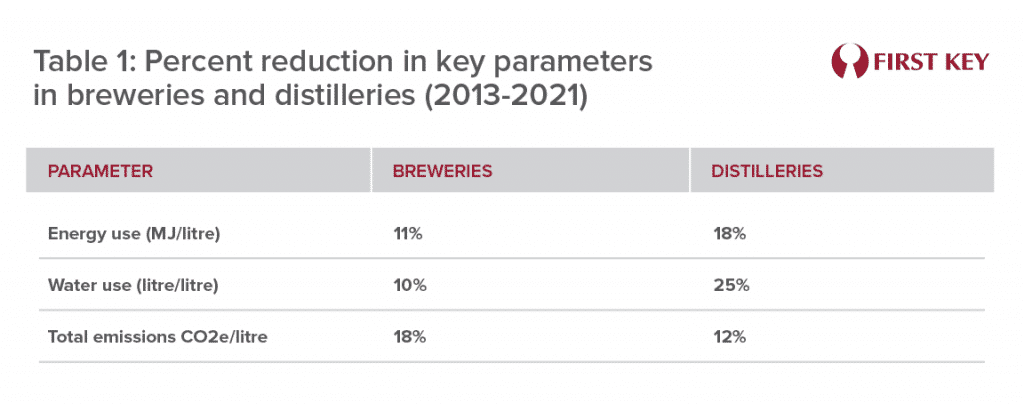

Between 2013-2020 has been significant reduction in energy and water use in breweries and distilleries around the globe giving an overall reduction in CO2 emissions (Table 1):

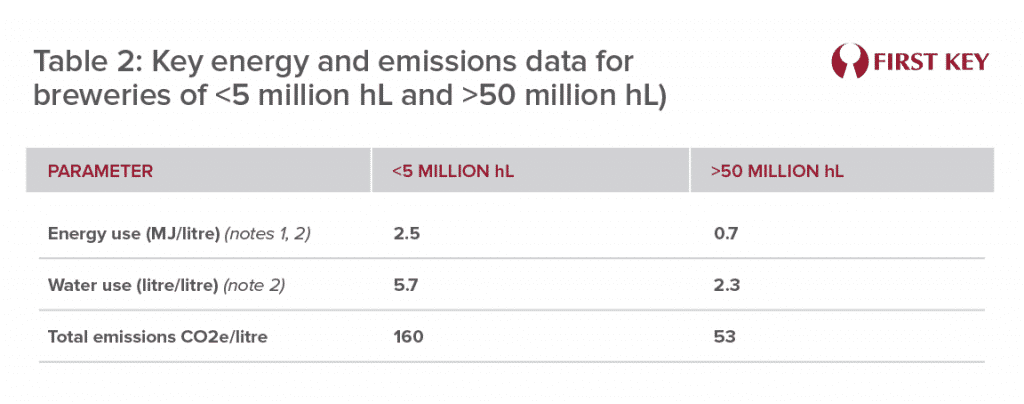

Size of brewing operation does impact the efficiency of operations considerably. Industry averages show this challenge. It is equally true that even larger breweries may not yet be as efficient as best in class (Table 2).

1: There is a balance between reducing emissions and total energy use. Legislation and the climate emergency are currently focussing more on emission reduction than energy efficiency

2: Some published data can be dramatically lower than current usage if there is considerable use of recycled water or green electricity generation and the report is of abstracted water or grid electricity supplied

What sort of initiatives are being used to achieve the reductions still required to reach Net Zero by 2050?

Packaging

- Switching from plastic to low carbon cardboard packaging and looking for the next innovation which could be new generation glass

- Reduction in weight of packaging:

- Plastic bottles: 40% already achieved by best in class

- 33cl cans: 55% weight reduction already made

- Glass bottle: 60% weight reduction achieved

- Procuring from low carbon suppliers

- Setting key performance indicators (KPIs) for increased recycled content or biodegradable content in plastic

Waste

- Use of waste materials for brewing wort production (bread, cheese whey, baked goods)

- Use of brewery wastewater or spent grains to create methane via anaerobic digestion which drives an electricity generator

- Recovery of CO2 from fermenters is increasingly important to change a waste into a valorised product for reuse. Also a switch to CO2 generated from less GHG intense activities such as anaerobic digestion of green feedstocks which has a much lower carbon footprint than generation as a by-product of ammonia-based fertilisers

Energy source

- Switch to green electricity supply. Caution here is that some suppliers classify green as technology that was installed long before the calculations were made on climate change so best-in-class switch is to demand new green electricity dedicated to use in house

- Fuel switching from natural gas to biomass generated heat/steam which can achieve 90% GHG reduction

- Solar electricity or heat generation through photovoltaic (PV) or other solar panels

Regenerative Agriculture

- Working with the cereal supply chain to promote best agricultural practices that use lower GHG impact fertilisers and could even generate carbon credits and improve soil quality

Water

- Recycling to reduce freshwater abstraction or use

- Water treatment to provide potable water for use in washing or in process as technology has improved. To be most carbon efficient this also requires use of green electricity for the ultrafiltration/reverse osmosis filters most commonly used

Financial impact of sustainability

Cost of new technology can be seen as a barrier to investment especially by the craft sector which may not have access to the funds of larger corporate businesses. There are, however, many examples of craft breweries making very similar plans aligned with the types of initiative described in this article. It is advisable to use operational savings generated through investment in green technology to provide cash for further improvement. Surveys indicate that the craft sector will not necessarily have access to the expertise available to evaluate new technology. It is therefore essential for the industry to work collaboratively to jointly improve the carbon impact of brewing to ensure it is recognised as an industry seriously promoting a net zero agenda.

There is a drive to attach financial impact to climate risk through initiatives such as the Taskforce for Climate-Related Financial Disclosures (TCFD). TCFD was created in 2015 at the request of the G20 to the Financial Stability Board to improve reporting of climate-related financial information. It focusses on four pillars: governance to address climate related risks and opportunities; strategy to define the real impact of climate change on business assets; risk definition and management; metrics and targets to assess climate risks and opportunities. The UN Principles for Responsible Investment (PRI) endorses TCFD-aligned reporting. The intention is to better guide the allocation of capital and inform investment decisions. It is essential that data disclosed is relevant, specific, clear, consistent, comparable, verifiable, and reported in a timely manner.

The Sustainability Accounting Standards Board (SASB) is a similar framework for investors, insurers, and debt holders. SASB focuses on quantifying and reporting the outward environmental impacts and risks of an organization’s performance, while TCFD addresses how climate change might impact the organization’s ability to create value. There are currently 8 breweries reporting via SASB and 8 via TCFD of the almost 3,000 companies registered on each platform.

Setting an internal carbon price (ICC) can help quantify the financial impact of business operations on climate change. Using a recognized financial carbon market an internal price of carbon for emissions can be calculated. A comparison of the cost of spending on capital against the potential cost in buying carbon offsets to reach carbon neutral is then possible. Some food and beverage companies have chosen to allocate this amount to a carbon neutrality fund which can be competed for by internal departments wishing to implement GHG saving projects. Others have decided to buy all their offsets now and work to rebuild profitability through innovation. The latter is clearly a riskier strategy, but both approaches show how financial impact and climate risk are now being placed at the heart of business operations.

To manage such important strategic impacts on company performance a detailed carbon roadmap is essential. It must have specific projects and technologies identified and encompass carbon intensity reduction to hit the global 2050 target. It should address the triple bottom line benefit: People, Profit, Planet. It is a business advantage to make profit in an environmentally sensitive way that engages and impresses all stakeholders and provides open, honest, verifiable proof through reporting and build the internal skills capital by attracting those who are impressed by climate friendly businesses. Carbon reduction of course cannot be at the risk of stalling progress on other important aspects such as waste and water reduction and packaging. A good plan will identify the point at which offsets or insets become the only way to become neutral and formally apportion capital spend required to implement the chosen technological pathway within the company. It will include a requirement of supply chain partners to make similar plans. Only by all partners working together will we achieve our collective goals.

By Dr. Nigel Davies, Senior Advisor, Technical Services and Sustainability

[1] https://www.beveragedaily.com/Article/2021/10/20/AB-InBev-turns-to-green-hydrogen-for-Magor-brewery

[2] https://www.theheinekencompany.com/newsroom/heineken-part-of-the-hydrogen-revolution/

[3] https://sciencebasedtargets.org/

[4] https://www.smithschool.ox.ac.uk/publications/reports/Oxford-Offsetting-Principles-2020.pdf The Oxford Principles for net zero aligned carbon offsetting

[5] https://www.unglobalcompact.org/what-is-gc/mission/principles