From the earliest detailed records of cask hopping in England in the 15th century, we know that the intent of adding hops to the cask was to clarify and preserve the beer – most beers were aged for at least a year on hops – sometimes on a sea voyage. The flavor and aroma enhancement were a secondary benefit. Effectiveness of hopping was measured in salability of the beer after a long ship voyage or a short wagon-ride. Today, we have many more methods and criteria for assessing the success of dry-hopping and our primary goals are no longer tied to the preservative qualities of hops – we have other control methods. For the vast majority of brewers, the goal of dry-hopping is to enhance the hop flavor and aroma of the beer while preserving the freshness of those hop flavors.

Fresh hop cones have been placed directly in casks for aging for centuries. This method is still in use today, but several advances have been made in hop technology as well as new extraction techniques in the brewery. When Fritz Maytag re-imagined dry-hopping in his “modern” Anchor Brewery in the 1970’s in San Francisco he used nylon mesh bags roughly the size of large pillows stuffed with 7-10 pounds of whole hops per bag and deposited these directly in the aging tank prior to filling the tank. The beer then sat on the hops for roughly 10 days, sometimes longer. This method was still in place at Anchor for certain beers until the brewery was closed in 2023.

Figure 1 – Whole cone hops stuffed in mesh bags ready to go in the tank.

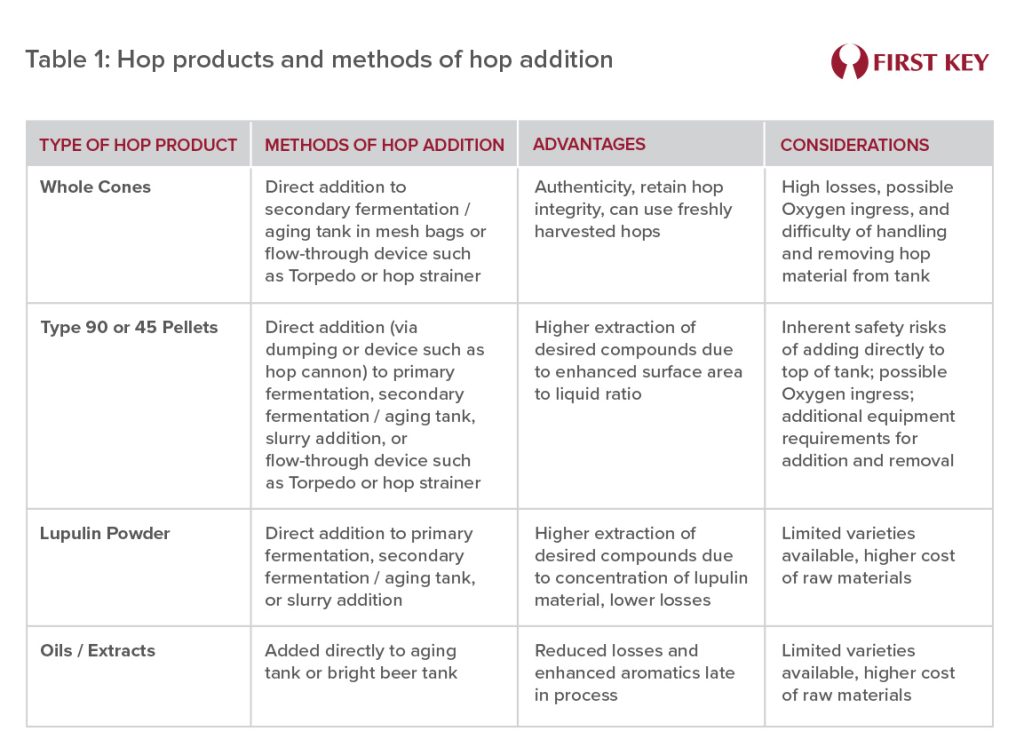

Most brewers in the 21st century use hop pellets for both hot-side and cold-side hopping. There are many different hop products available to brewers today and they are summarized with advantages and considerations in the table below.

Today, Type 90 hop pellets are the most prevalent, but Type 45 (concentrated) are also widely available, as are pre-isomerized pellets and even pure lupulin powder. All of these can be used in dry-hopping and methods range from directly infusing the pellets into the aging beer to flow-through devices and equipment. The method of introducing the hops into the tank, how long the beer stays in contact with the hops, and what types, varieties and amounts of hops are all the choice of the brewer depending on desired flavor and aroma profile of the beer.

The brewer has a host of choices for introducing hops to the beer, from hop cannons, torpedoes, and other dosing technologies. Whether it is chosen to have the beer flow through the stationary hops in a vessel, or to rest the beer on top of the hops, the goal is extraction of flavor and aroma compounds without extracting more bitterness or undesirable flavor compounds such as tannins and polyphenols. The timing is therefore critical. Many brewers have designed methods to maximize extraction of terpenes and thiols while minimizing time on hops to prevent over-extraction of tannins while minimizing the effect of “hop creep.”

Figure 2 – Flow-through style dry-hopping tank

The addition of pure lupin powder, hop oils or cryo-hops also minimizes the vegetative components of the hop while providing maximal extraction of desired flavor and aroma compounds. These can also lower losses from dry-hopping.

Safety & Quality Considerations when Dry Hopping

There is no task that is so important that it cannot be done safely. This applies to dry-hopping in the brewery as well as every other process or activity. There are certain risks that present themselves when adding hops to beer at any point in the process – boiling wort presents obvious hazards, but fermenting beer at much milder temperatures brings its own set of threats to employee safety. Pressurized vessels should never be opened without venting them properly. If tanks need to be vented, they must always be vented safely to outside the building since CO2 is an asphyxiant. CO2 monitoring devices should be employed as a measure of safety if tanks must be vented indoors. Tanks should never be entered by people unless proper confined space entry procedures are followed. If working from heights is required to add hops through the top of a tank, then ladder or scissor lift safety techniques and proper working from heights protocols must be followed. There are many horror stories of brewers opening a tank under pressure while at the top of a wobbly ladder, there is even a term, “hop geyser” for hops and beer spraying violently out of a tank – this is not a badge of honor, it is an unnecessary risk – don’t let it happen to you or your employees!

The quality considerations when dry-hopping are many and varied. Dissolved Oxygen (DO) control is paramount whenever adding hops, or any other ingredient, post-primary fermentation. Care must be taken to minimize the introduction of oxygen at this point in the process. Methods to be employed are pre-wetting of hops, ideally in de-aerated water or beer, purging all vessels and lines with CO2 or nitrogen, and/ or creating a de-aerated slurry of hop material and beer.

Microbiological control is also very important – introducing microbial contamination via hop handling equipment or the hops themselves must be minimized at this point in the process, one possible method is to slurry the hops in hot water prior to addition. Hops are a microbiological inhibitor, but they also may be a source of microbes. Care must be taken to minimize any possible contamination via hop-handling equipment. Frequent cleaning of all hop conveyance systems should be an integral part of the brewery master-cleaning plan.

Over-extraction of undesirable compounds such as tannins and herbal flavor compounds that give off garlic and onion-like aromatics is a significant risk from over-hopping at very high rates (>5 lb/bbl) or leaving the beer on the hops for too long (several days or more). Hopping during high-temperature fermentations also introduces some variability to the flavor extraction process and is highly dependent on yeast cell concentration at the time of dry-hopping. Recent studies have shown that thiol production is greatly enhanced due to biotransformation of hop compounds during fermentation.

“Hop Creep” is a phenomenon that has been identified and characterized as a continued fermentative process that occurs due to the introduction of un-boiled hops into a “finished” beer during secondary fermentation or aging. The enzymes present in the un-boiled hops allow fermentable sugars to be created and therefore additional fermentation byproducts continue to form in the beer long after fermentation was thought to be completed. The Technical Brief from the Brewers Association on Hop Creep authored by Arnbjørn Stokholm and Thomas H. Shellhammer provides excellent details on this phenomenon as does the following First Key article: Hop Creep: Causes and Remedies.

Any dry-hopping regimen devised by a brewery needs to take into account all of the following variables: wort composition, yeast strain and cell concentration, hop varieties, type of hop product, means of addition, timing of addition – primary fermentation, secondary fermentation, cold aging or cask; amount of hops added, length of time on hops, temperature at which beer and hops are held, and the method of removal of hops from beer. With such a myriad of possible methods for dry-hopping and a variety of different hop products available as well as multitudes of hop varieties to choose from it is important that the brewer consider all of these factors as well as brewery design and layout prior to selecting the method and materials, and always with safety, beer quality and desired flavor and aroma outcome in mind.

References

Bamforth, C.W. & Fox, G.P. Scientific Principles of Malting and Brewing. Chapter 13 – Hops and Hop Products (pp. 155-166) American Society of Brewing Chemists, St. Paul, MN (2023)

Brown, P. Hops and Glory Pan, Macmillan London, UK, (2009)

Ockert, K. The Craft Brewer’s Guide to Best Practices – Volume 3 – Dry Hopping, Sours and Funky Beer Production, Packaging and Utilities. Chapter 1 – Developing Hop Flavor (pp. 1 – 53) Master Brewers Association of the Americas. St. Paul, MN (2024)

Oladokun, O., James, S., Cowley, T., Smart, K., Hort, J., & Cook, D. Dry-hopping: The effects of temperature and hop variety on the bittering profiles and properties of resultant beers. Monatsschrift für Brauwissenschaft, 70, 188. (2017)

Steele, M. IPA, Brewing Techniques, Recipes and the Evolution of India Pale Ale. Brewers Publications, Boulder, CO (2012)

Stockholm, A. & Shellhammer, T. Hop Creep – Technical Brief. Brewers Association (2020)

Young, J. and Fox, G.P. A Fresh Perspective on Hop Composition: The Discovery of Starch in HopCones (Humulus lupulus) Journal of the American Society of Brewing Chemists (2025)

Walz, M., Schoenberger, C., & Krottenhaler, M. Influence of Dry Hopping Timing on Hop Aroma Brewing and Beverage Industry Magazine, 1/2025