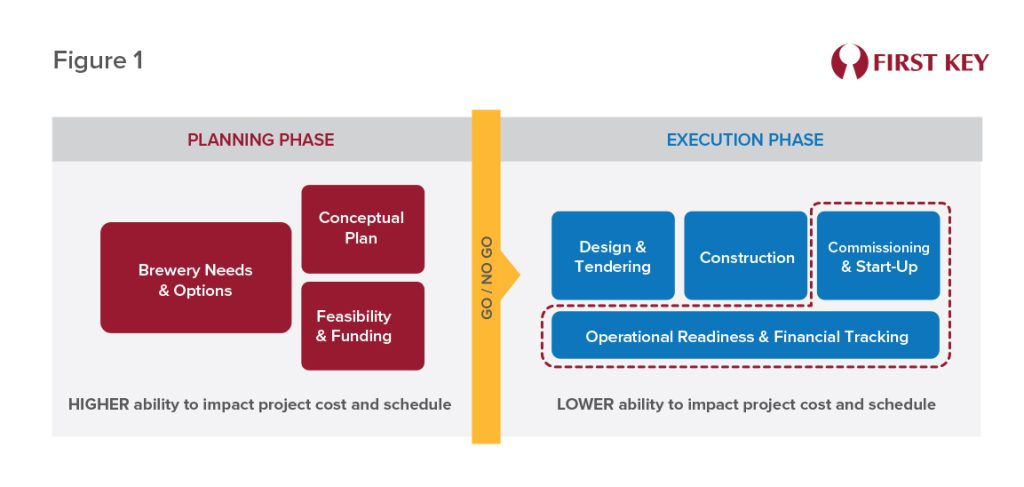

Much of the financial investment for a brewery project or process change will be required during the Construction Phase, but that investment will not generate value until proper commissioning and startup deliver the desired new outcome. Your brewery is looking for new or changed functionality, not just new equipment. Outcomes are critical, and to better guarantee positive results, the project team should have a comprehensive commissioning and start up plan.

Planning for the end of the project should have been outlined from the start during the Project Plan. This plan should define who the startup team is and what the required outcomes are so everyone involved is working towards achieving the desired results. The Design and Tendering Phase supports formalizing the requirements for equipment or process performance and establishing clear criteria and timelines for contractors. During the Construction Phase, the project plan is executed with some adjustments for unforeseen issues or conditions.

Let’s bring it to life!

Some of the most adrenaline pumping and fulfilling times within any project are when the equipment or process you’ve invested so much of the brewery’s time and money into makes its first can, finishes its first brew, achieves a desired setpoint or is filled with wort for the first time. Just don’t underestimate how involved startup and commissioning can be to go from the first can off a new can line to operating your new can line at the contracted can per minute throughput specification.

Your commissioning and startup plan is best managed as a sub-project within the larger project with similar aspects but focused on bringing things to life, and this includes items such as the following:

- The Schedule:

- When will construction be completed to allow for testing to begin?

- How long will it take to complete adequate testing?

- When is production expecting to have the new functionality operating at full capacity?

- Who is part of the Commissioning Team:

- Equipment experts / Supplier representatives

- Integrators / Programmers

- Construction representatives

- Front Line Team – Brewers / Operators

- Operational Management

- What will be tested?

- Equipment readiness

- Types of procedures (e.g. startup, shutdown, different types or speeds of operation, cleaning/CIP)

- What are the performance requirements that must be satisfied?

- How quickly does this performance need to ramp up?

- Readiness for Operational Takeover

- When and what level of operation will the Brewery take over the equipment without support from the suppliers or contractors?

- What safety training or changed safety practices are required as part of the change?

- What operational training is required?

- Who requires this training? How will this be executed? Will there be a super-user?

- What standard operating procedures (SOPs) are required? Who will write them?

- What quality checks are required? Who will perform these?

- What maintenance training is required?

- What new supplies or materials are required? Are these ordered?

The Commissioning & Startup Leader is not necessarily the overall Project Manager. Typically, the best Commissioning Leaders are representatives from the operational departments who will take over the equipment or process after completion of the project. This aids in fostering ownership and accountability for the success of the functionality of the project’s result. This Commissioning Team Leader should be involved throughout the entire project to provide feedback and perspective from the operational point of view. “Project Teams that are well integrated with technical, construction and operational members from start to finish are the most successful”, shares Mike Gerhart, First Key’s Senior Advisor, Technical Services. “Having a constant eye on how each move within a project will impact the operational effectiveness results in a faster ramp up time and better ownership by brewers and operators”, adds Gerhart.

As a project nears the end of the Construction Phase, there are some critical steps and practices to take to prepare and make the startup and commissioning efforts more efficient and effective:

Cleaning & Transitioning the Site from Construction to Commissioning

Although it is good practice to keep the area clean throughout the entire Construction Phase, as construction nears completion it is even more important to clean up the impacted brewery areas to transition from construction to full operations again. There will be construction materials stored in various locations and all of these materials should be removed. This helps to visually convey that startup and commissioning are an operational aspect of the project not a construction aspect. Giving all the construction areas a good deep cleaning to remove construction dust and debris is also critical.

Labelling & Marking

This may seem like a small detail, but remember: new is not normal! Labelling piping, valves, equipment along with marking new forklift lanes will aid in reducing confusion during troubleshooting efforts that will likely come up. Labelling & marking is not likely to be a one-time event as during commissioning new locations for added clarity will come up – these are important opportunities for the commissioning team to document and take action.

Dry Walk

As a project team, completing a dry walk can be a helpful way to identify any remaining deficiencies or operational setup needs prior to more involved testing or initial production. Including representatives from all aspects of the project team (e.g. construction, engineering, operations, quality) together for the walk is important to get all their perspectives. This can be a starting point to review new material and process routes, ensuring all new equipment is in place and reviewing the effectiveness of cleaning and labelling completed to date, and evaluating new safety risks to ensure they are well managed. During this walk it is helpful to structure the walk such that it follows the new process flow. For instance, walking from empty can load on to finished case removal is an effective way to view a new can line. Similarly, walking a new wort line from brewhouse pump and by each fermenter can aid in validating flow path, valve order, risk of quality issues, etc.

Key aspects of the commissioning and startup plan will include:

Equipment Check Out

Once construction is completed and especially as electrical components are being livened up it is important to “check out” each piece of equipment. An Equipment Check Out list should be defined as part of the Commissioning & Startup Plan and typically involves validation of:

- Power Panels – test voltage, frequency, and power quality at each distribution point.

- Operator touchscreen or Control Panels (also called Human-Machine Interfaces or HMIs) – test buttons and functionality on the screens and how they control components of the equipment or start/stop process steps.

- Instruments & Control Devices – test signal from programmable logic controller (PLC) or feedback from instruments back to the PLC

- Motor Rotation – check that the wiring is setup to drive the motor in the required direction.

- Compressed Air distribution – validate that all new or altered equipment have live compressed air.

- Valves:

- Default Position – check what the normal position of the valve is: valves can be setup to be “normally open” or “normally closed” which is important to the overall process flow.

- Response – using the PLC, pulse valves from close to open and from open to closed to validate valve setup and PLC are aligned.

- Conveyers:

- Test direction (see motor rotation)

- Validate that the conveyer chain is moving freely

- Verify that conveyer transitions upstream and downstream are smooth

Water Testing

Prior to introducing expensive materials and potentially harmful chemicals, it is best to complete Water Testing of equipment. This step allows for a safe way to check for system leaks and process flows, routing and sequences with low risk. As an example, a water brew is best to run through a new brewhouse system to validate new brewing processes without wasting grains, hops, enzymes, etc. Water Testing is also a great way to flush out construction materials in the piping ahead of initial Clean-In-Place (CIP) processes. A similar concept to be applied to packaging equipment testing by using unbranded cans, cartons, etc. instead of more expensive finished materials. Testing pressure safety valves during the water test is a safe way to confirm that the equipment is set up correctly.

Performance Testing

Once Dry and Water Testing are completed, it’s time to perform a first production run to test the performance of the overall new system, not just the subcomponents. This is always a very exciting and nerve-racking time – but this is what the project is all about! Completing the commissioning plan and taking the time to complete pre-testing will make this a smoother process. Be sure to test all safety devices and systems as part of the performance test and document the tests done and their results.

For process projects, it is typical to start this performance testing with CIPs to ensure new piping and equipment is cleaned and that the critical cleaning processes are in place prior to any product production. Testing the limits of the new system by identifying the potential failure modes in advance is critical to ensure a comprehensive assessment.

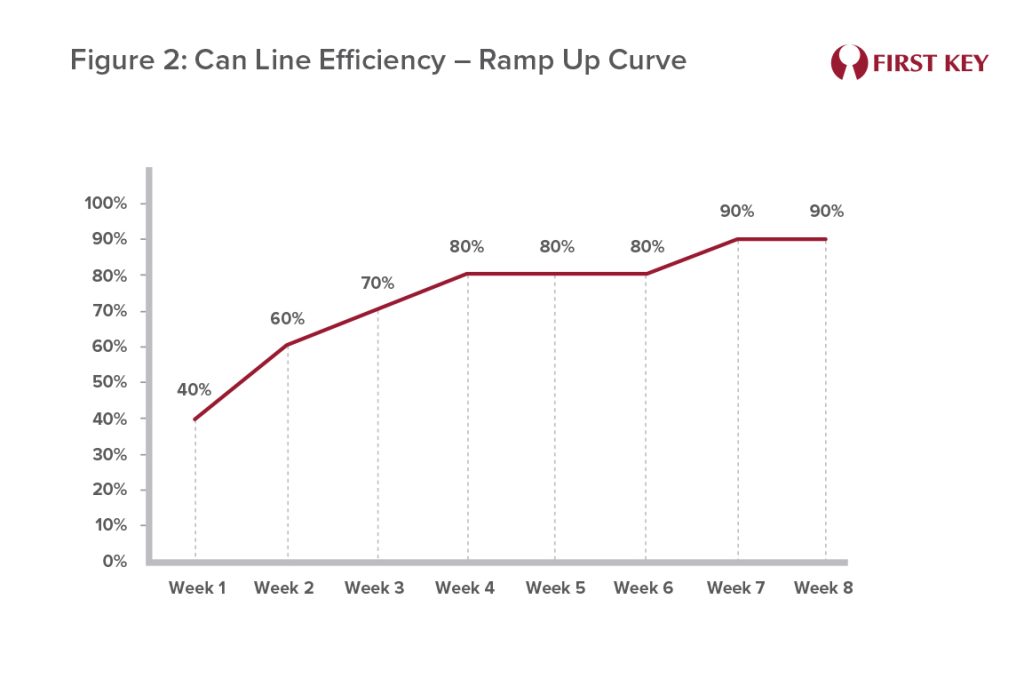

Be sure to de-rate the packaging line speed and book additional production time for this initial performance testing as it will be slow and less efficient since it is new and there is a natural learning curve associated with startups. For instance, with new packaging equipment, there is typically a “ramp up” period which has a gradual increase in line efficiency (see example below).

Performance Acceptance & Warranty Period

As an outcome of the Performance Testing, equipment contracts often have a formal Performance Acceptance process which defines the achievement of performance specifications. These are typically focused on the equipment capabilities alone since other impacts (e.g. operator training or responsiveness) may fall outside of the control of the contractor. This is a critical aspect of the project and is essential to define well during the Design and Tendering Phase.

Warranty for the system’s performance or equipment reliability typically has a defined period included as part of any contract. It is important that the brewery is very focused on monitoring the performance to validate that this performance is sustained during this warranty period to protect its investment.

Project Close Out

Projects don’t live on forever although their impacts can be long lasting within the brewery. The Project Manager should collect documentation and technical details throughout the entire project for reference in the future. In the end, these critical files are shared with the entire brewery within a centralized electronic folder along with handing over a collection of paperwork, equipment manuals, warranty certificates, etc. A final series of meetings with the project team to review performance and any open issues is valuable to ensure the project’s outcomes are set up for long-term success. These meetings are also useful to celebrate the project team’s work together and discuss lessons learned to improve for the next project.

This is the final article of the Project Management Best Practices Series. If you have questions about Project Management, please contact us. We would be interested in your suggestions on other Project Management topics you would like First Key Insights on.